Published on Apr 02, 2024

The measurement of electric current strength is not always easy, especially when the measured signal requires further electronic conditioning. Simply connecting an ammeter to an electrical circuit and reading out the value is no longer enough. The current signal must be fed into a computer in which sensors convert current into a proportional voltage with minimal influence on the measured circuit.

The basic sensor requirements are galvanic isolation and a high bandwidth, usually from DC up to at least 100 kHz. Conventional current measurement systems therefore tend to be physically large and technically complex.

Conventional sensors are physically large and technically complex; also they have disadvantages as stated above. Hence they are replaced by magnetoresistive current sensors. The magnetic field sensors are based on the magnetoresistive effect. These sensors can be easily fabricated by means of thin film technologies wit widths and lengths in the micrometer range. To reduce temperature dependence, they are usually configured as a half bridge or a full bridge. In one arm of the bridge, the barber poles are placed in opposite directions above the two magnetoresistors, so that in the presence of a magnetic field the value of the first resistor increases and the value of the second decreases.

The anisotropic magnetoresistive effect is known to be present in a whole family of ferromagnetic alloys. Most of these alloys are composed of iron, nickel, and chromium, and may be primary or ternary. They have in common a more or less strong anisotropy in their magnetic properties. Whenever these materials are exposed to a magnetic field during crystal formation, a preferred orientation in magnetization will result. The same happens when the materials are forced into shape that is a mechanical anisotropy is imposed.

It is found that changing the orientation of the magnetic moment in the wire caused a current passing through it to change correspondingly. The orientation could be changed by apply in an external magnetic field, and generally an increase in current was observed. This phenomenon is called anisotropic magnetoresistive effect.

The ferromagnetic materials can be deposited as thin films and structured into small strips that are typically 40mm thick,10mm wide, and 100mm long. In most general case, the electrical resistance of AMR material depends on the angle between the direction of the magnetization, and the direction of the current going through it. When the current and magnetic moment are parallel, the resistance of the strip is greatest; when they are at a 90 degree angle to each bother, it is smallest.

Magnetoresistive field sensors are usually configures as a half or full bridge. The barber poles are positioned such that in the presence of magnetic field the value of first resistor increases and that of second decreases.

The ferromagnetic materials can be formed into thin films and can be structured into small strips that are typically 40mm thick, 10mm wide and 100mm long. This makes the fabrication of the sensor very easy

To reduce temperature dependence, they are configured as half bridge or as full bridge.

Measured quantity is directly proportional to the output. The current flowing through Permalloy conductor generates a magnetic field that exactly compensates the magnetic field generated in the conductor that is to be measured. Hence the device is linear.

Magnetoresistive sensors are not affected by the external magnetic field. This is achieved by the full bridge configuration of four magneto resistors. Barber poles have the same orientation in the two arms, so no external field will affect the system.

Permalloy can be drawn into thin sheets or thin films or thin strands. Hence they are compact and easy to fabricate and cheap.

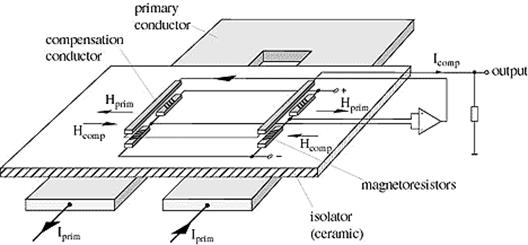

Magnetic field sensors based on the magnetoresistive effect can be easily fabricated by means of thin film technologies with widths and lengths in micrometer range. For best performance, these sensors must have a very good linearity between the measured quantity and the output signal. Even when improved by the barber poles, the linearity magnetoresistive sensor is not very high, so the compensation principle used on hall sensors is also applied here. An electrically isolated aluminum compensation conductor is integrated in the same substrate above the Permalloy resistors.

The current flowing through this conductor generates a magnetic field exactly compensates that of the conductor to be unmeasured. In this way the MR element always work at the same operating point; their nonlinearity therefore becomes irrelevant. The temperature dependence is also almost completely eliminated. The current in the compensation conductor is strictly proportional to the measured amplitude of the field; the voltage drop across a resistor forms the electrical output signal.

Magnetoresistive sensors, as are hall elements are very well suited or the measurement of electric currents. In such applications it is important that external magnetic fields do not distort the measurement. This achieved by forming a full bridge are specially separated. The barber poles have the same orientation in the two arms, so that only a field difference between the two positions is sensed. This configuration is insensitive to external homogenous perturbation fields. The primary conductor is U shaped under the substrate, so that the magnetic fields acting on the two arms of the bridge have the same amplitude but opposite directions. This way the voltage signals of the two half-bridges are added.

The sensors require neither a core nor a magnetic shielding, and can therefore be assembled in a very compact and cheap way. The output is calibrated by a laser trimming process or by a digital calibration.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |